Wolfenden launch Agri-Stride: a hybrid flooring range focused on animal welfare and the environment – including a world-first

Building on the positive impacts our hybrid slats are showing on-farm, for dairy productivity and herd welfare, Wolfenden’s latest innovation is the AgriStride range. The first two products – AgriStride Classic and AgriStride Vario – provide the cutting-edge innovation that farmers expect from Wolfenden, the only UK-based manufacturer of hybrid flooring solutions.

British farmers must meet significant environmental challenges on the journey to net zero, and efficient slurry management coupled with ammonia emission reduction is critical. These impact on animal welfare, where cleaner floors and better slurry management make for better hoof health and lower vet bills. Wolfenden continually invest in R&D to help farmers meet these challenges. The new AgriStride range incorporates all of Wolfenden’s research into hybrid design, for better herd welfare and more flexible flooring options to meet changing on-farm infrastructure needs and regulatory requirements.

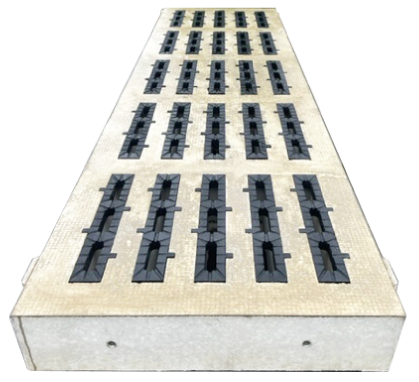

The AgriStride Range: The combination of 50% rubber with 50% concrete makes for a flooring which provides exceptional comfort and grip, leading to more natural animal movement and optimum hoof health. With a high number of drainage holes in the rubber cassettes, rapid dispersal of liquids and solids keeps floors drier and cleaner, helping to reduce surface level ammonia emissions by up to 60%.

The AgriStride range is both environmentally-friendly and economical. The rubber inserts have a minimum 10-year lifespan, and when they do need to be replaced, the concrete slats remain in situ – ensuring minimal expense or disruption. The inserts can also be switched out and swapped at any time to allow for different animals to be housed throughout the farming year, giving even greater flexibility and cost-savings. The AgriStride range is designed to work with wider passages – proven to increase yield in first lactation cows and offering better animal welfare.

AgriStride Classic: Class leading axle loadings from 10 tonnes up to 40 tonnes help futureproof your farm, as vehicles become larger and heavier. With 15’ and 16’ length options, the Classic slat incorporates the AgriStride range benefit of increasing yield for first lactation cows and is ideal for wide spanning passageways.

AgriStride Classic: Class leading axle loadings from 10 tonnes up to 40 tonnes help futureproof your farm, as vehicles become larger and heavier. With 15’ and 16’ length options, the Classic slat incorporates the AgriStride range benefit of increasing yield for first lactation cows and is ideal for wide spanning passageways.

The Agri-Stride Classic is the latest iteration of Wolfenden’s hybrid slat, designed to help futureproof farm infrastructure and address the imminent need to decarbonise, while helping improve herd welfare for better productivity.

Agri-Stride Vario: Wolfenden’s newest product*, and the second in the AgriStride range, is a world-first. Dual-spanning, no other diagonal cover can be used over a narrow channel and a wide passage. A 16’ span combined with a 5’ 4” width makes it longer and wider than competitor products.

Agri-Stride Vario: Wolfenden’s newest product*, and the second in the AgriStride range, is a world-first. Dual-spanning, no other diagonal cover can be used over a narrow channel and a wide passage. A 16’ span combined with a 5’ 4” width makes it longer and wider than competitor products.

As with all of Wolfenden’s investment in new product design and testing, the emphasis is on providing farmers with the greatest flexibility, to help futureproof infrastructure and reduce costs. The chevron design of the Vario insert layouts – working on a diagonal – has been shown to be highly effective for floor cleaning, meaning even better slurry management for reduced emissions and better hoof health. Again, these are suitable for multi-animal environments, where the rubber inserts can be swapped between options designed for different animals’ needs.

Richard Moody, Wolfenden’s Managing Director, comments,

“The new AgriStride range is the culmination of Wolfenden’s significant investment in R&D, with time spent building relationships and taking advice from some of UK agriculture’s leading experts.

AgriStride products will benefit our customers, both at the large- and the smaller-scale. We’re already receiving great feedback from farmers who are using our hybrid solutions, with positive results for animal welfare and slurry management.

Our new AgriStride range demonstrates Wolfenden’s commitment to helping British farmers to improve productivity, to lower emissions, and to improve their herds’ welfare.”

*Patent pending