Hybrid Supa Slats in action: modernising a dairy for more efficient farming and a happier, healthier herd

When Andrew and Richard Pidcock-Matkin and family decided to invest in the dairy housing at their family farm in Nottinghamshire, they came to Wolfenden for advice on adapting an existing building so that it could incorporate the latest developments in robotic milking, extend their slurry stores, and include the latest hybrid flooring products for hoof health and cow comfort.

Andrew and Richard explain the reasons behind the project,

“We needed to add additional slurry storage, and we decided to invest in robotics to help make milking easier and less labour intensive. Like many farmers, we know the issues with recruiting skilled labour, so we wanted to make our milking as efficient as possible. We already have Wolfenden slats in other sheds on the farm, and have been really happy with the way they work – keeping the floors clean – so we were keen to go back to them for this new project.”

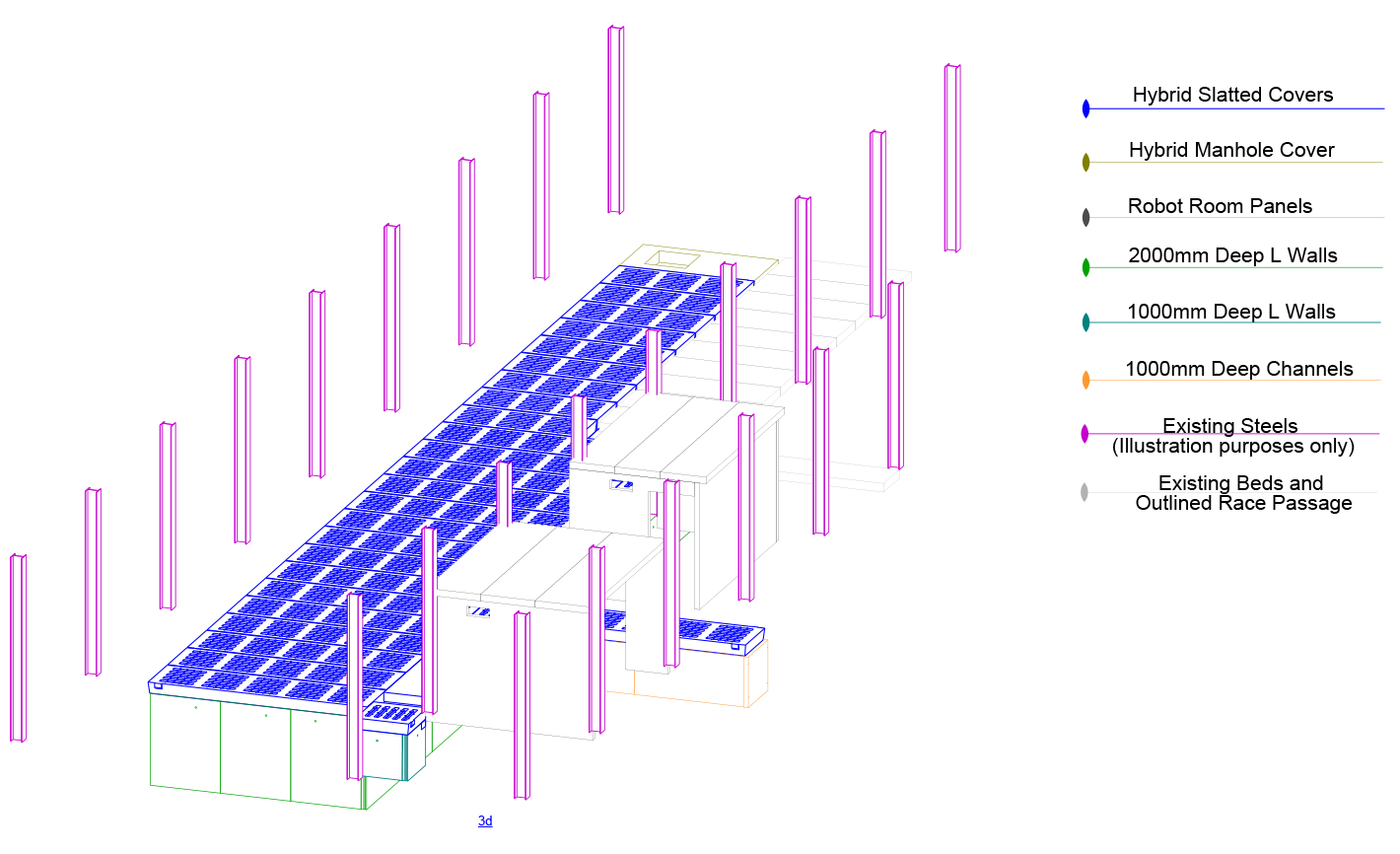

For slurry management, Wolfenden incorporated their L wall units into the design. These were specified at two different depths – 1000mm and 2000mm – creating two tanks, side by side, which separate parlour washings from the slurry and are serviced by Wolfenden’s Supa Deep Channels. These new tanks match the depth of an existing tank at the opposite end of the building, so helping to maximise the benefits of a refurbishment and avoid unnecessary work and costs. Wolfenden products have been incorporated throughout the project, both slurry management and flooring, and include new Hybrid slatted covers and Hybrid manhole covers.

The brothers have been closely observing the impact of the new environment on the herd, and the cows are settling well into their new robotic milking routine, with calf heifers’ yield already showing improvement. They’re particularly pleased with the impact of the Hybrid Supa Slats,

“The rubber inserts in the slats are better for the cows’ feet. They don’t slip. With this better grip, cows are happy to stand on the flooring and it seems to have helped them get used to the new robotic milking system. It gives them more confidence.”

Commenting on the finished project, Richard Moody, managing director at Wolfenden, adds,

“It is great to see our new Hybrid products working on-farm in precisely the way we envisaged when we began investing in and working on new product development. This farm faces the same issues as many in the dairy industry today, and their approach is forward-thinking. Working with them to create an environment designed for efficiency and herd health has been a pleasure.”